Product Details

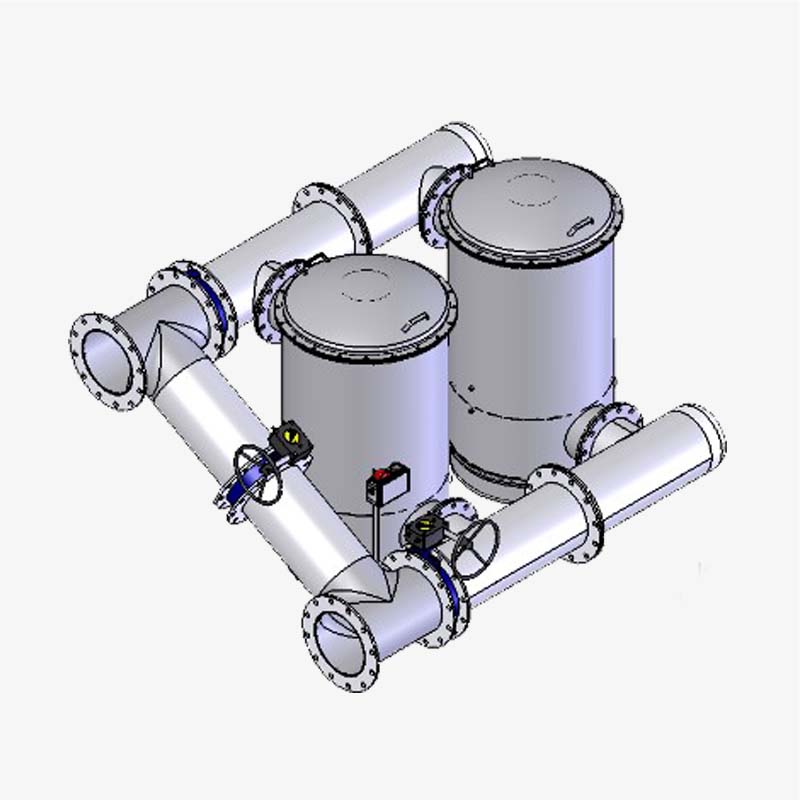

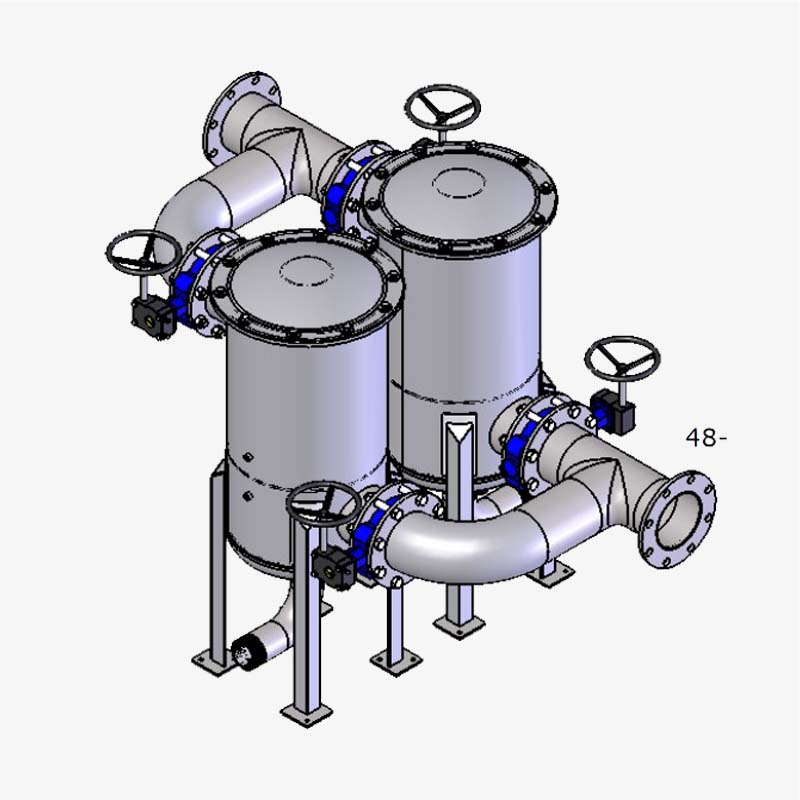

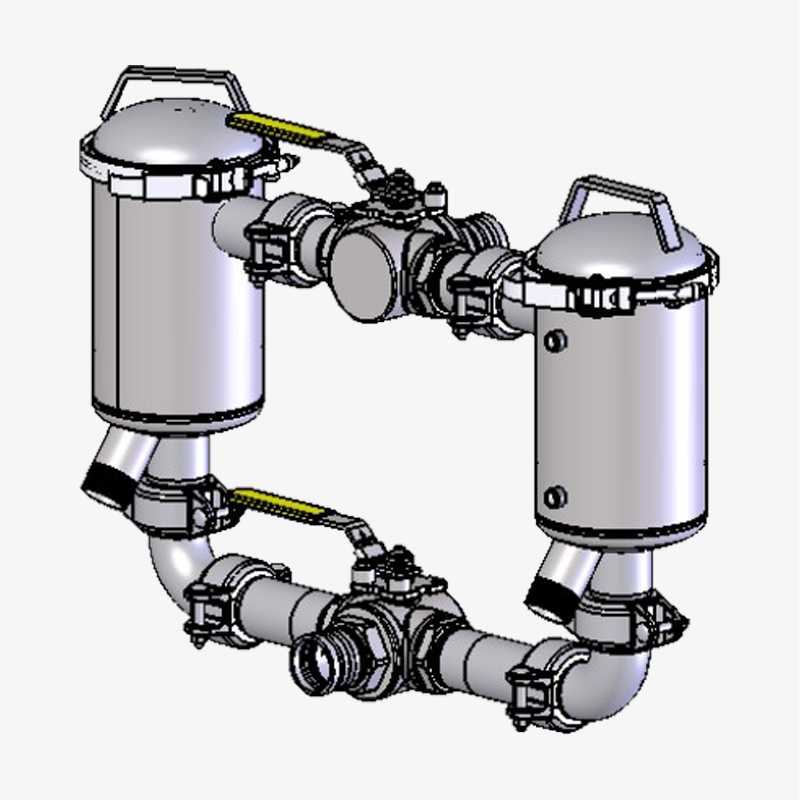

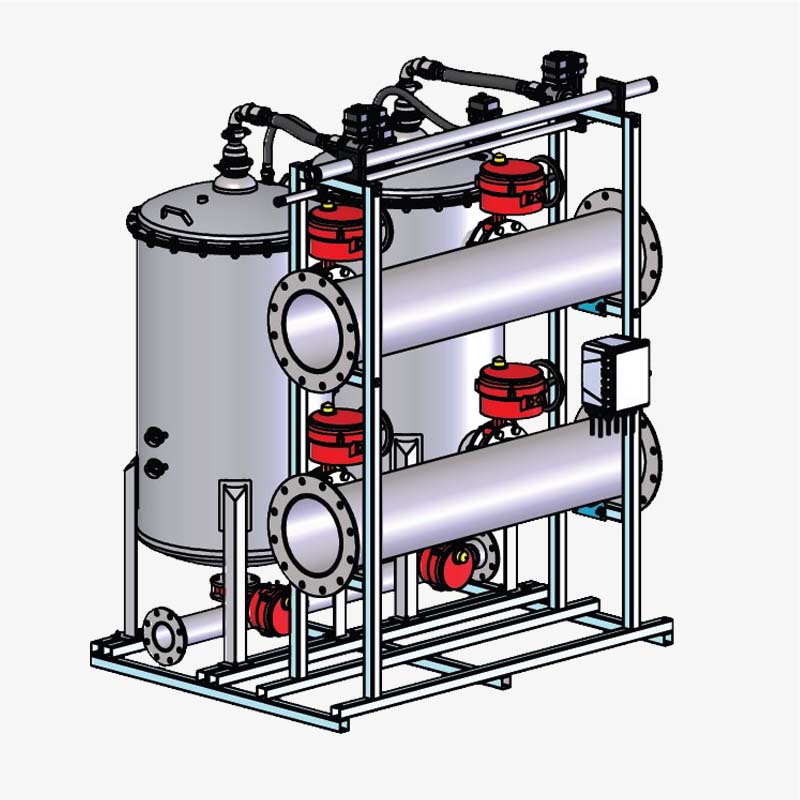

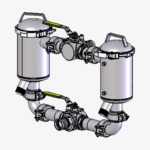

The Thompson Strainer is our highly efficient, patented stainless steel strainer which features a large conical screen, offering substantially more screen surface area versus traditional y-strainers or basket strainers. All models operate with less than a 1-PSI pressure loss at maximum flow when clean. Our Thompson Strainer Duplex systems are assembled, tested and ready to ship.

Each Duplex package includes:

- Thompson Strainers

- High-quality isolation valves

- Optional State-of-the-Art Instrumentation Packages

The Duplex systems arrive completely assembled and are value engineered to deliver superior performance and long-term reliability.