Product Details

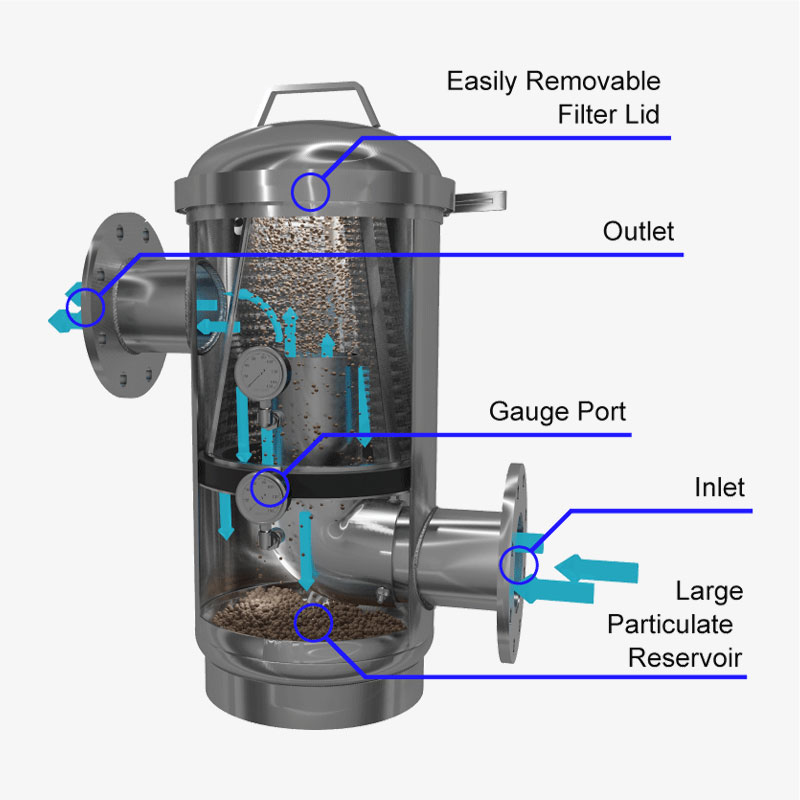

The Thompson strainer has a unique design: as water enters the bottom of the strainer housing and flows upward, heavier debris and particulate is accelerated downward, away from the conical screen, into the large debris reservoir at the base of the strainer. The particulate is then flushed from the reservoir via the debris flush port. For a demonstration on how it works, see the video below.

Due to the large amount of screen surface area, all models operate with less than a 1-PSI pressure loss at maximum flow when clean. The strainers are available with a wide variety of screen mesh options, ranging from large perforated hole-openings down to approximately 50-micron. They can be customized to fit the specific requirements of the project and can be outfitted with optional instrumentation packages or our rinse nozzle.